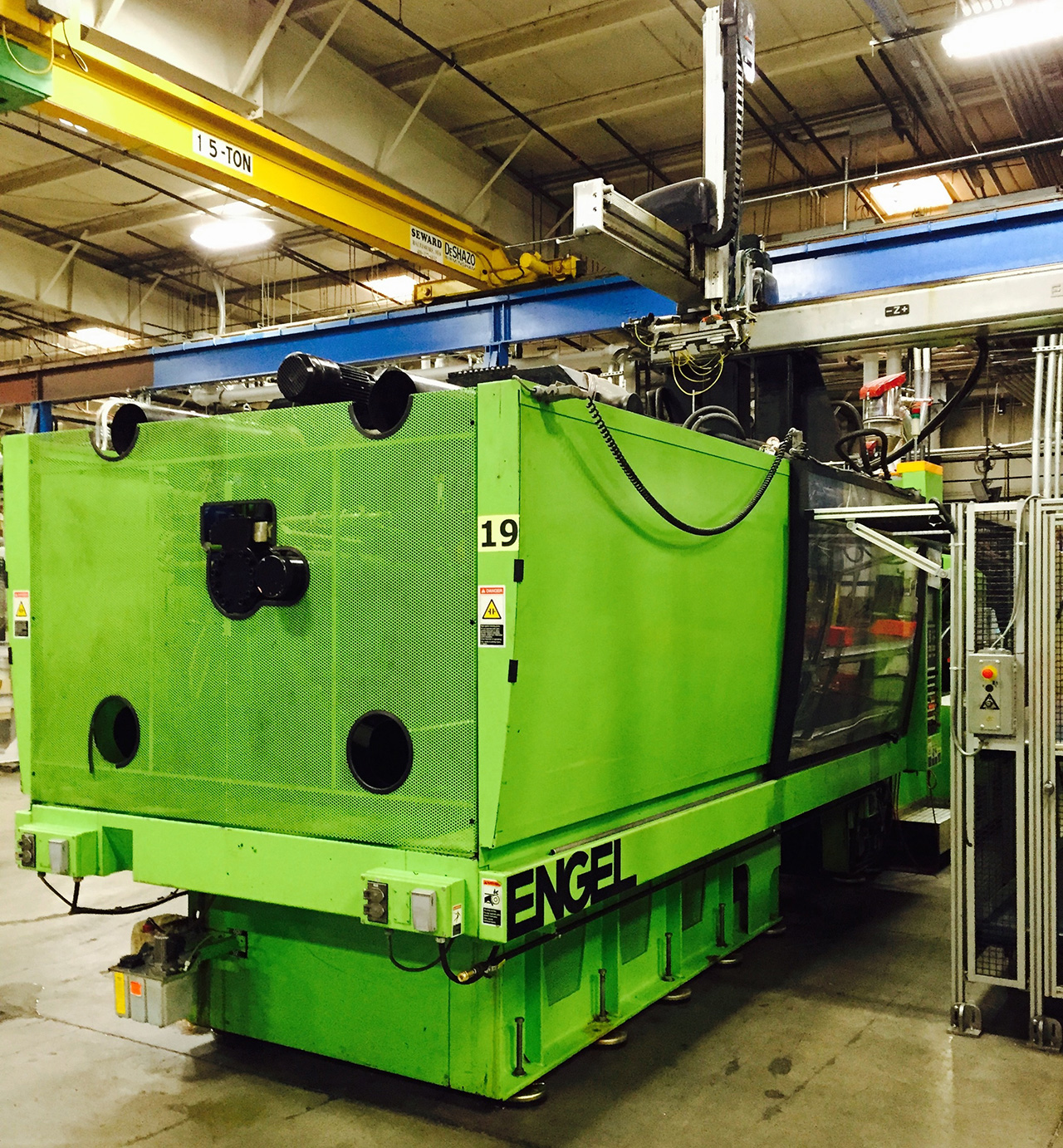

5 Injection Molding Maintenance Mistakes To Avoid

Effective injection molding equipment maintenance is the backbone of any high-volume plastics operation. Yet many shops fall prey to common pitfalls that shorten press life, increase downtime, and drive up repair costs. Below are the top five injection molding maintenance mistakes—and the proven remedies to keep your line running smoothly. 1. Skipping Daily Lubrication Mistake: Operators skip greasing tie bars, toggle joints, ejector guides, and other lubrication points under the assumption that electric or servo-driven systems “don’t need it.” Impact: Metal-to-metal wear accelerates, leading to increased friction, erratic clamp force, and premature bushing failure. Solution: Implement a concise daily maintenance... read more